Case Study: Everquip

Case Study: Everquip

Optimising processes to eliminate a business bottleneck and increase productivity and profitability...

Everquip is a manufacturer of vehicle inspection pits for the commercial vehicle and rail industries.

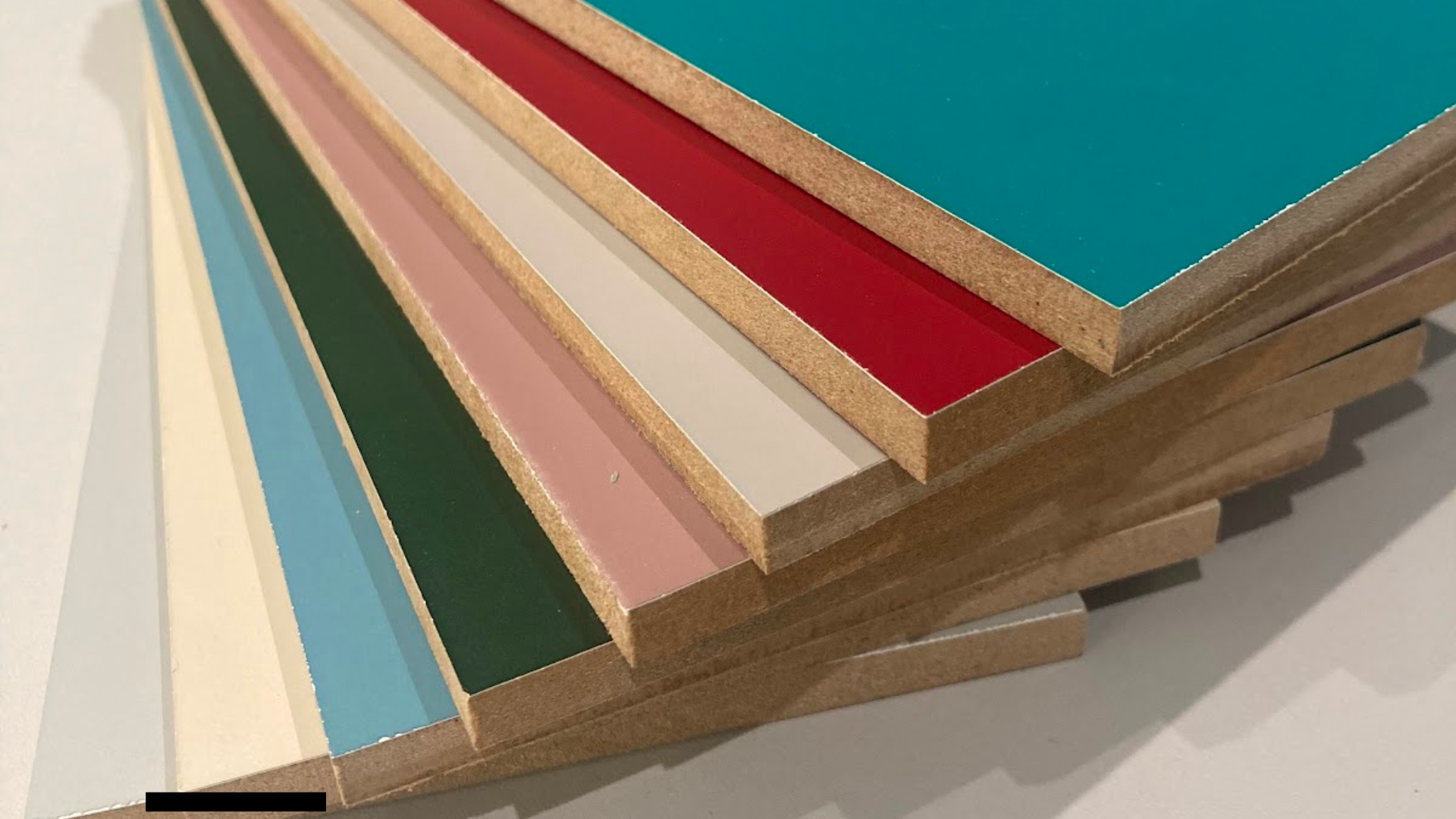

It is highly important that they are able to achieve a high gloss white finish for optimum light reflectance as this aids the inspection work. Likewise, the coating requires a durable finish to withstand impact from tools being used in a relatively confined space.

Analysis

Assessment of all aspects of the coating process

Everquip were initially dealing with a 3-product, 4-coat system which was significantly limiting their spray shop output and as a result creating a production bottleneck.

In an attempt to switch to a single-pack coating, it was taking a long time for coatings to thoroughly cure to full hardness, this was subsequently causing products to get damaged during the transit/installation process. This was a lengthy and costly process which couldn't continue.

Implementation

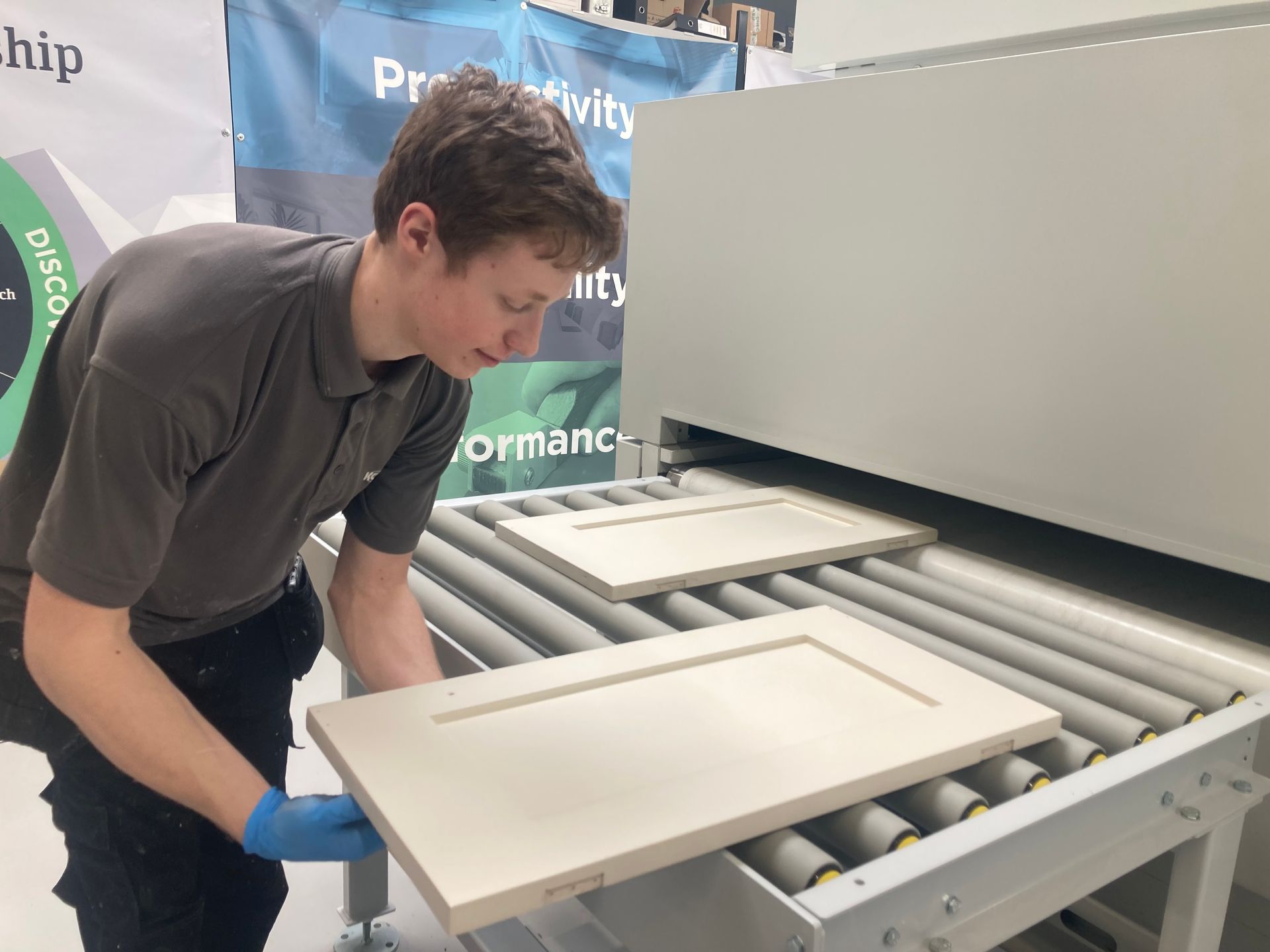

Developed optimised processes to improve production output

From reviewing the current coatings and production processes Kortec implemented methods they believed would help to develop processes that increase productivity and profitability.

Therefore, Everquip was introduced to a high-performance / high gloss 2-pack primer and finish coating. This included an accelerator for rapid curing (even during colder conditions). As this would allow the team to take back valuable time and avoid costly damages from occurring during transit or installation.

Related Article: '13 Essential Considerations When Choosing The Right AC Coating System'

Ongoing Client Benefits

Structured assessment on a weekly basis

Kortec reduced Everquip's 4-coat process to a 2-coat process which meant a 50% improvement in processing time, which positively enables Everquip to eliminate the bottleneck of their business.

A full product cure can be achieved within 16 hours, which significantly reduces transit/installation damage and lowers business expenses.

"What a really helpful set of guys nothing is too much trouble. Great knowledge of the products, And great products to."

- Paul Drewery, Production Manager

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.