5 Most Common Concerns With A Water-Based Coating System for Wood

5 Most Common Concerns With A Water-Based Coating System for Wood

Water-based coatings are cost-effective, durable and eco-friendly, however many do have concerns...

Water-based coating systems have strong advantages for producing an excellent finish that is environmentally friendly and cost-effective. However due to historical limitations affecting these systems, there are widespread concerns around them across our clients’ industries.

Aren’t they expensive compared to alternative systems?

Don’t they dry very slowly?

I believe they can’t match the durability of other coatings?

Isn’t it very hard to get a good quality finish, especially on MDF?

5 Most Common Concerns Addressed:

- Cost

- Drying

- Preparation

- Durability

- Negative History

1. Cost - Are water-based coatings expensive?

Water-based paints and lacquers may be more expensive based on a direct per litre/kg comparison to other products. This is due to the fact that the resins and other raw materials used in these coatings are typically more expensive than the solvent-based equivalents

However, to be a fair comparison the whole cost of a coating system for wood needs to be considered. For a solvent-based system, this can include:

- Hardeners or activators - often these cost more than the paint itself

- Thinners – for both diluting & cleaning

- Waste disposal – typically classed as hazardous

- Mixing/pot life – causes waste of both time and material

For a water-based wood coatings these only apply minimally at most:

- Hardeners are not normally required

- Water can be used for dilution and cleaning

- Waste is not hazardous, and permits can often be obtained for simple disposal

- If no hardener is required, the mixing/pot life issues do not apply

When this is all evaluated together, water-based wood coating systems often turn out to be one of the most affordable solutions for many firms.

Related Article: 'Save £1000’s, How Much Does A Water-Based Coatings System Cost?'

2. Drying - Are water-based coatings slow to cure?

The length of the drying process for water-based coating systems is ultimately dependent on each company's drying facilities and capabilities.

|Some believe that water-based products are always slower drying than solvent – with modern technology this is definitely not the case, assuming reasonably good heat and consistent airflow are available.

Where an environment isn't temperature controlled or the level of airflow is poor, drying times can still be considerably extended, particularly if heavy coats are applied.

In a good environment with some heat and consistent airflow, a water-based system can be dried as quickly or faster than solvent-based alternatives.

Related Article: 'What Wood Coating Type Gives The Best Overall Finish & Durability?'

3. Preparation - Can a water-based coating system achieve a good finish?

It is widely understood that water-based wood coatings have the potential to raise fibres on materials such as Mdf, particularly with the first coat.

As long as the preparation between coats is adequate, this does not need to be an issue. Taking some time and care to ensure the first coat is accurately applied and followed by good pre-sanding and denibbing will ensure that subsequent coats eliminate the fibres raised by the first coat.

We have repeatedly proved that an excellent finish can be obtained even on low-quality MDF, from a system as simple as two coats of primer, followed by one coat of topcoat

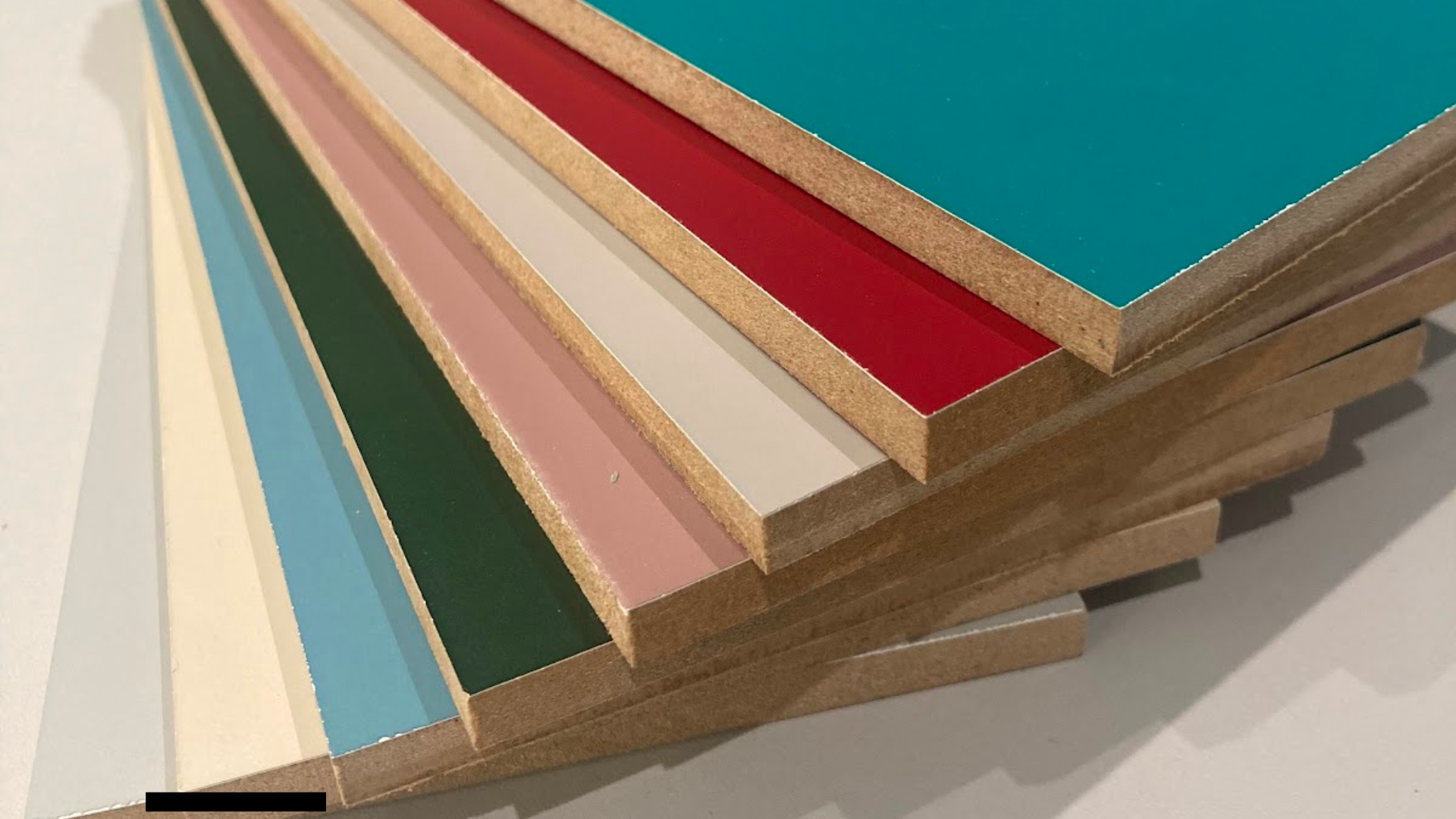

4. Durability - Can a water-based coating compete?

Durability includes a number of different factors when it comes to a wood coating system.

Scratch resistance is a common measure, and there is a traditional view that water-based coatings perform poorly. This was certainly true in the past, but modern coatings can achieve superb results

This also applies to adhesion, scrape testing, coin marking etc - a high-quality water-based coating system can compete with the best alternatives on the market.

FIRA (Furniture Industry Research Association) standards also include tests such as coffee-staining - we have several systems that have achieved the FIRA Gold standard, giving you full assurance that water-based coating systems can achieve excellent durability results.

Readers Also Like: '5 Things You Should Know About The Transition From Solvent To Water-Based Coatings'

5. Negative History - Why have water-based coating systems been viewed as poor?

Water-based technology has been used within the industry for over 15 years - it was being heavily promoted in the early 2000's, but at that point it was failing to live up to the standards of solvent-based paints. Slow-drying products with inferior durability and inconsistent quality left many companies with a negative experience of water-based technology.

Since that time research and development of water-based technology has continually progressed with exceptional results in the products now available. Unfortunately many that trialled water-based systems in the past have held onto their original negative perception and have been understandably reluctant to try it again.

With the technology available now the impressions received then are largely no longer accurate, but that psychological barrier is still a challenge that many companies face.

The continual innovation and proof of excellent outcomes will help to change perceptions and continue the change to trustworthy water-based wood coating technology, with all its environmental and efficiency benefits.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.