Case Study: Fowler & Gilbert

Case Study: Fowler & Gilbert

"Our aim was to try and find a system that would allow us speed up both our drying and handling time due to increases in production demand!"

Analysis

We looked into the chemistry of the type of paint being used

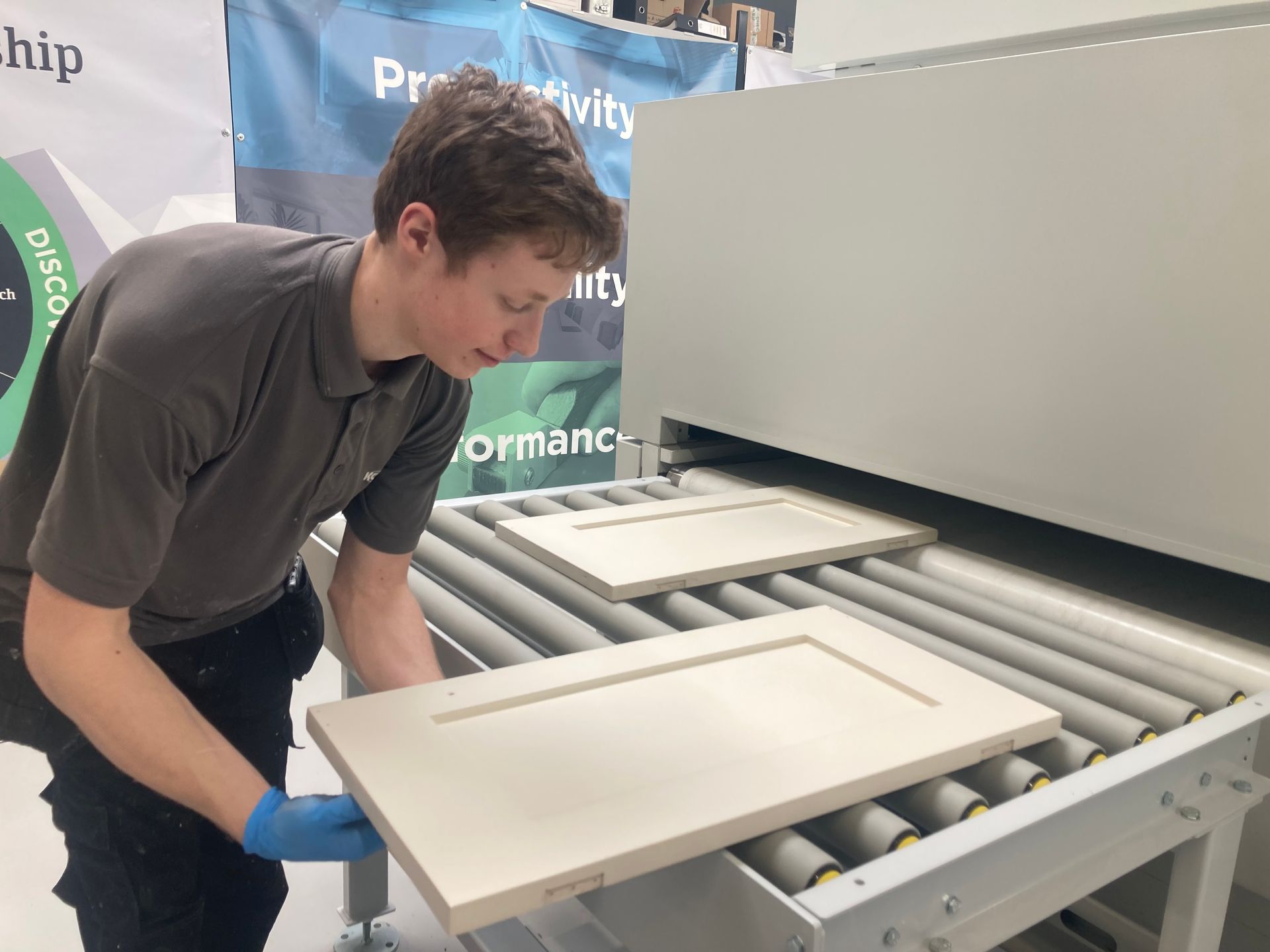

From our initial Investigate meeting, it was clear that Fowler & Gilbert already had a system that provided them with the correct durability and accreditation in the field. Their biggest headache was slow drying times, particularly in winter, which reduced the number of items per day that could go through the spray shop.

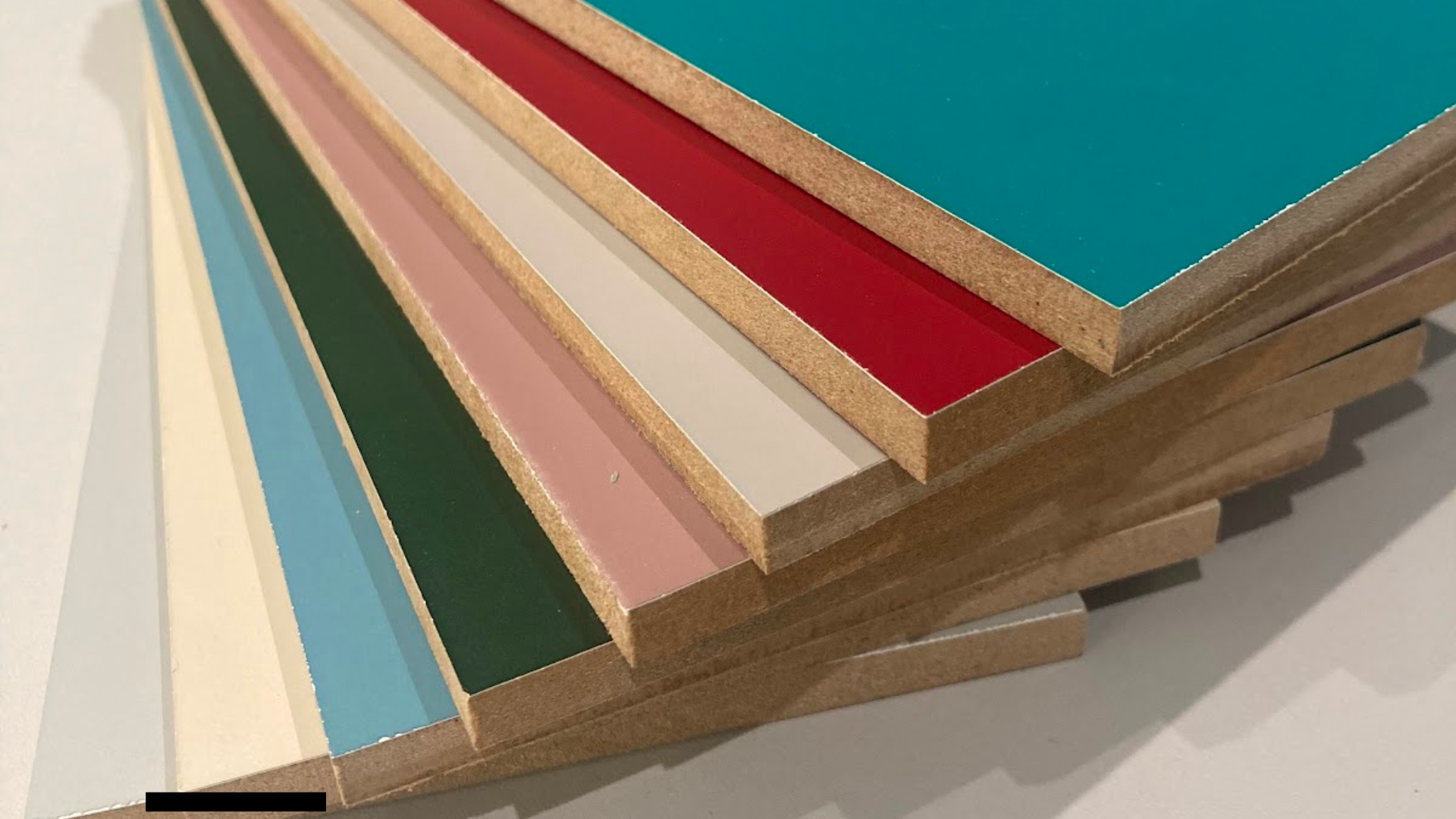

On further inspection, we also noticed that the opacity of their corporate green colour was relatively weak, meaning the sprayers were having to apply high film weights, again contributing to extended drying times.

Implementation

Formulated a paint with increased pigment opacity

Armed with the knowledge of what Fowler & Gilbert were seeking, we went away and assessed which product would best match their criteria. We were able to present them with a product we believed would have much higher opacity, as well as faster through cure, allowing them to increase production through the spray shop.

The on-site testing concluded that the client was now able to reduce their film weight by over 85 microns, which combined with the faster drying paint resin, provided them with a much faster thorough cure time.

Related Article: '5 Things You Should Know About The Transition From Solvent To Waterborne Coatings'

Ongoing Client Benefits

Lower film weights provide the client with several advantages moving forward

Due to the increased opacity of the proposed paint, and therefore the significant drop in required film weight, the client was able to reduce their overall paint expenditure, whilst still increasing production through their spray shop.

Our technical team provided some guidance on how to optimise drying times through the winter months, providing advice on spray techniques and building up smaller film weights, to keep handling time down to a minimum, and maximise spray shop productivity all year round.

Good planning with the client ensures we always have sufficient stock holding in place for them, in order to provide a constant, smooth transition from point of order through to delivery. Kortec also provides Jotun Steelmaster intumescent coatings required for special projects they get involved with.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.