Case Study: deVOL Kitchens

Case Study: deVOL Kitchens

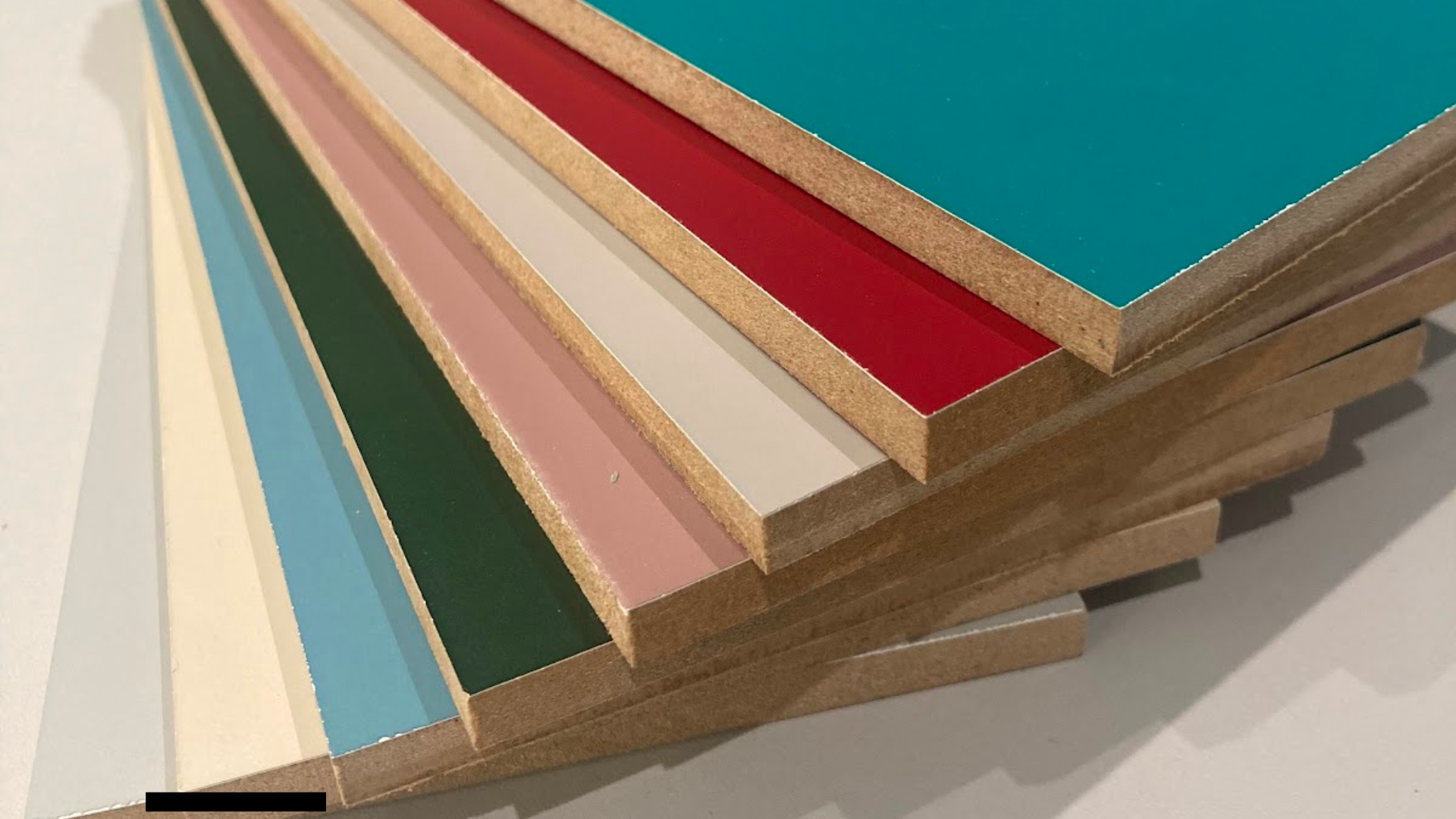

Previously facing issues of batch-to-batch colour consistency causing too many production disruptions.

deVOL has been a renowned design-led furniture manufacturer for almost 30 years. From dealing with issues of inconsistency, they reached out to Kortec in November 2017 to develop a reliable solution.

With approximately 20 standard colours (in addition to customer bespoke colours) deVOL required batch-to-batch consistency.

Analysis

Assessment of all aspects of the coating process

deVOL were already using a full water-based system, which has been their long-standing priority due to their company ethos of eco-friendly and sustainability. The main issue that both parties immediately highlighted was their need for a paint supplier to provide batch-to-batch consistency with their colours, as their current reject rate on quality control was above 50%.

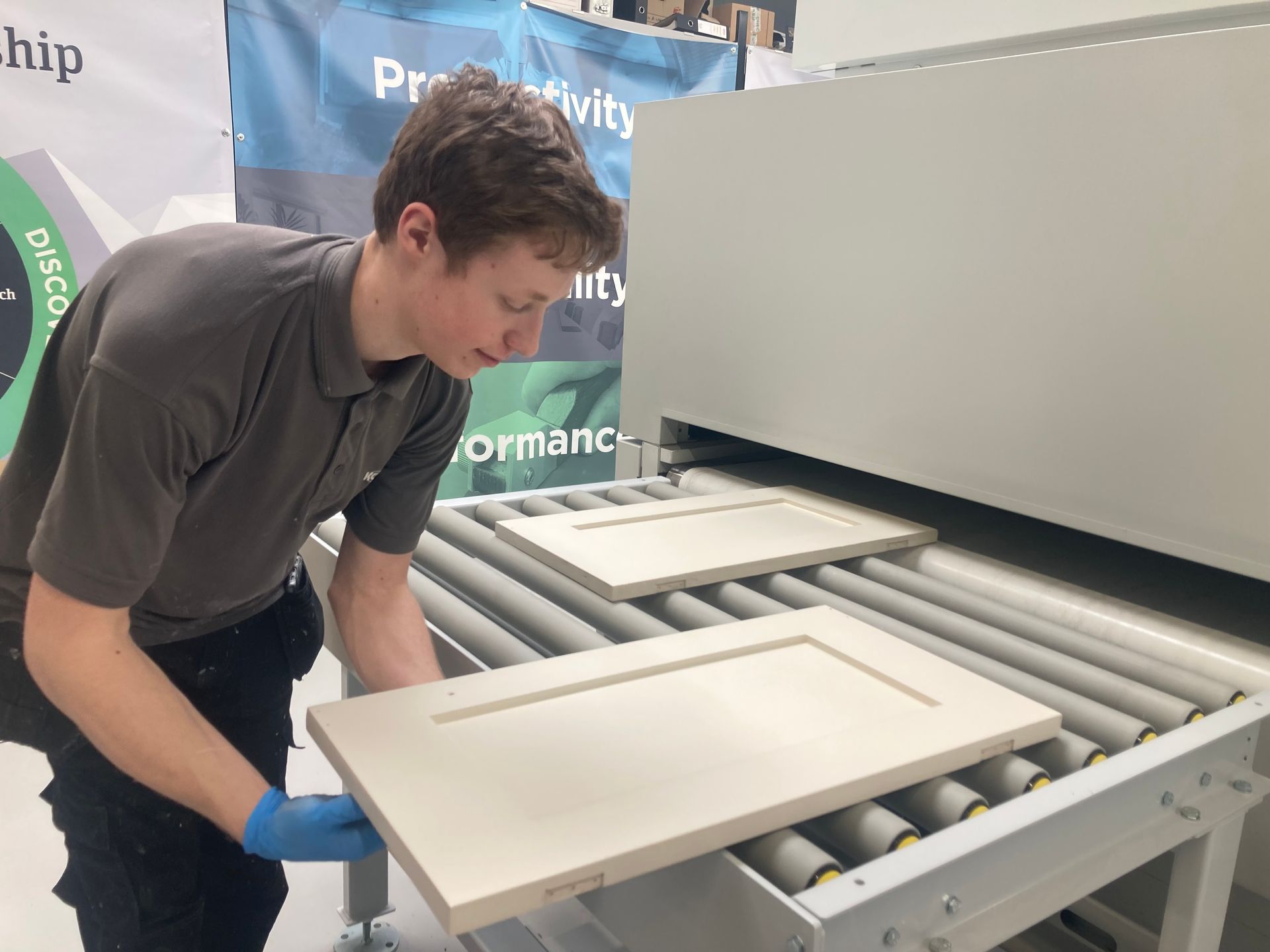

Implementation

All standard colours matched via KolorteqTM programme

As a starting point, we took their 15 core colours and matched these through our lab. Using the Kolorteq™ process, our lab technicians were able to achieve a 0.3 Delta E reading on all of these, within a 2-week window. The ongoing batch-to-batch readings were then monitored over the next 6-week period, 4 colours at a time before sign-off.

Related Article: 'What Coating Type Is The Cheapest For Internal Wood Finishing?'

Ongoing Client Benefits

Structured assessment on a weekly basis

As well as on-site assistance from our technical consultants, our Lab Manager was also in weekly contact with the Head of Paint at deVOL, sharing Delta E readings and ensuring all implementation of data was managed as efficiently as promised. Our aim was to provide multiple points of contact, to take the workload off deVOL staff and make this process as seamless as possible.

Within the first 6 weeks, due to the successful integration of the batch-to-batch colour consistency, we were able to reduce deVOL finishing department’s production time by over 30%. As a result of deVOL’s need for spray and brush coating, our team continued to work with different resins and pigments, to allow for a 0.3 Delta E reading, batch to batch, across both a sprayed and brushed finish.

George

deVOL Kitchens

"We have worked with Kortec for several years and throughout that time it has been very clear that our companies share a similar ethos. We require a very high standard of colour matching and consistency between batches, which is achieved without fail. The customer service is amiable, yet professional, and the level of communication is exactly what is required to keep our workshop running without delays. Painting furniture is never without complications but in Kortec, we know we have a reliable supplier and a team of experts who can provide support when required."

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.