Case Study : AM System

Case Study: AM System

“The aim was to find a Fire Rated system that provided the correct accreditation, without compromising the finish quality”

Analysis

For all their standard work AM System were using two-pack polyurethane coatings, as this gave them the perfect combination of high quality finish and fast turnaround time between coats.

However, they were getting an increasing number of projects requiring a fire rated (FR) finish, but to meet these they were having to sacrifice the quality of finish, as well as having to wait 24 hours between coats which had a big impact on production.

Implementation

We looked at our portfolio to provide a solution that best matched their requirements.

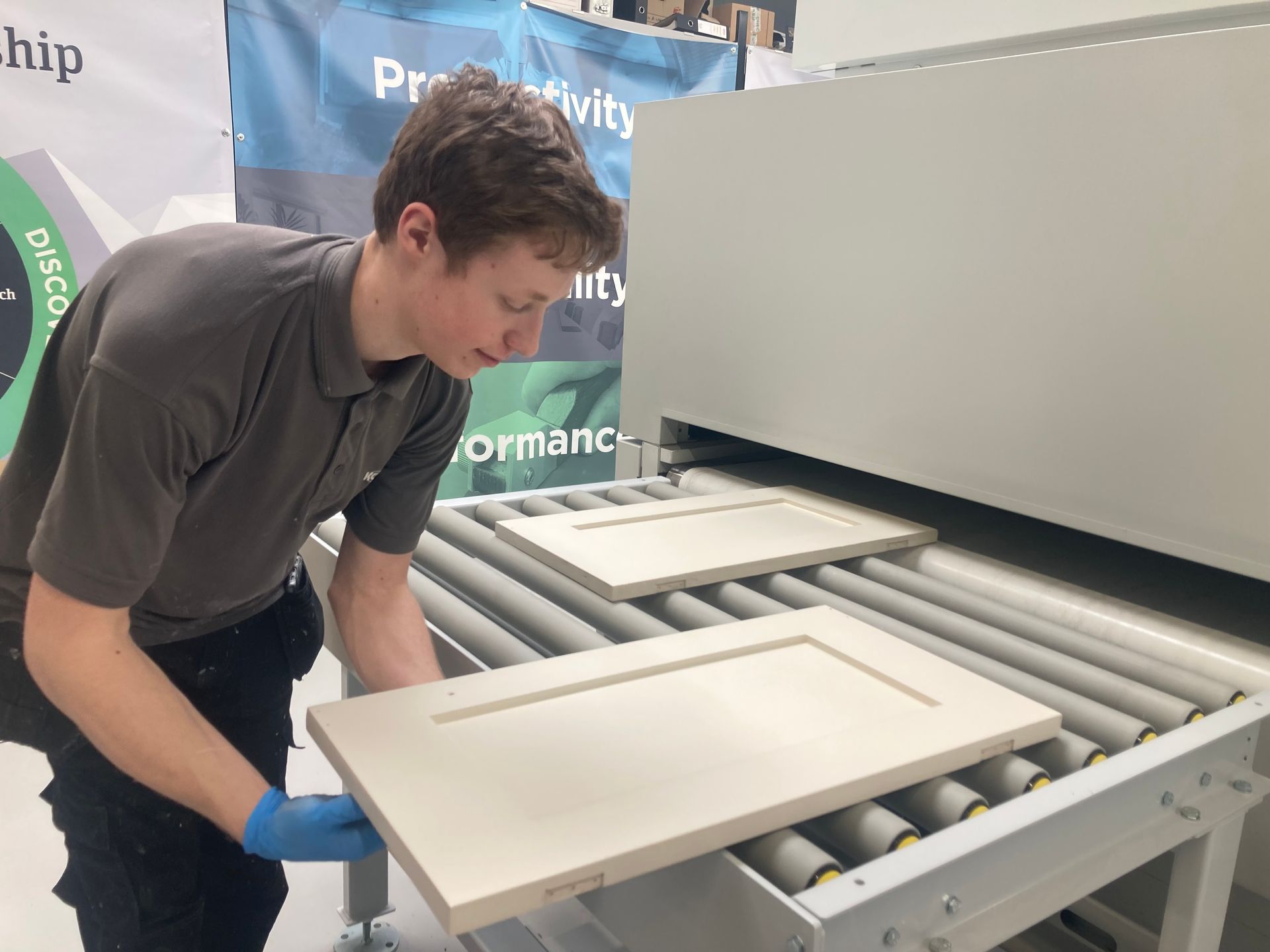

With the client already having a high volume of confidence and familiarity with two-pack polyurethane the aim was to be as consistent as possible with that, in order to hopefully provide the maximum benefits with minimal production changes. Our Sayerlack two-pack polyurethane FR system allows for 3 coats to be applied, but with minimal time between coats so all could be applied within one production shift. In addition it provided the usual finishing qualities of a PU, allowing the client to achieve a flat, factory finish unlike the ‘stipple’ or ‘milky’ finish associated with a lot of FR systems.

Ongoing Benefits

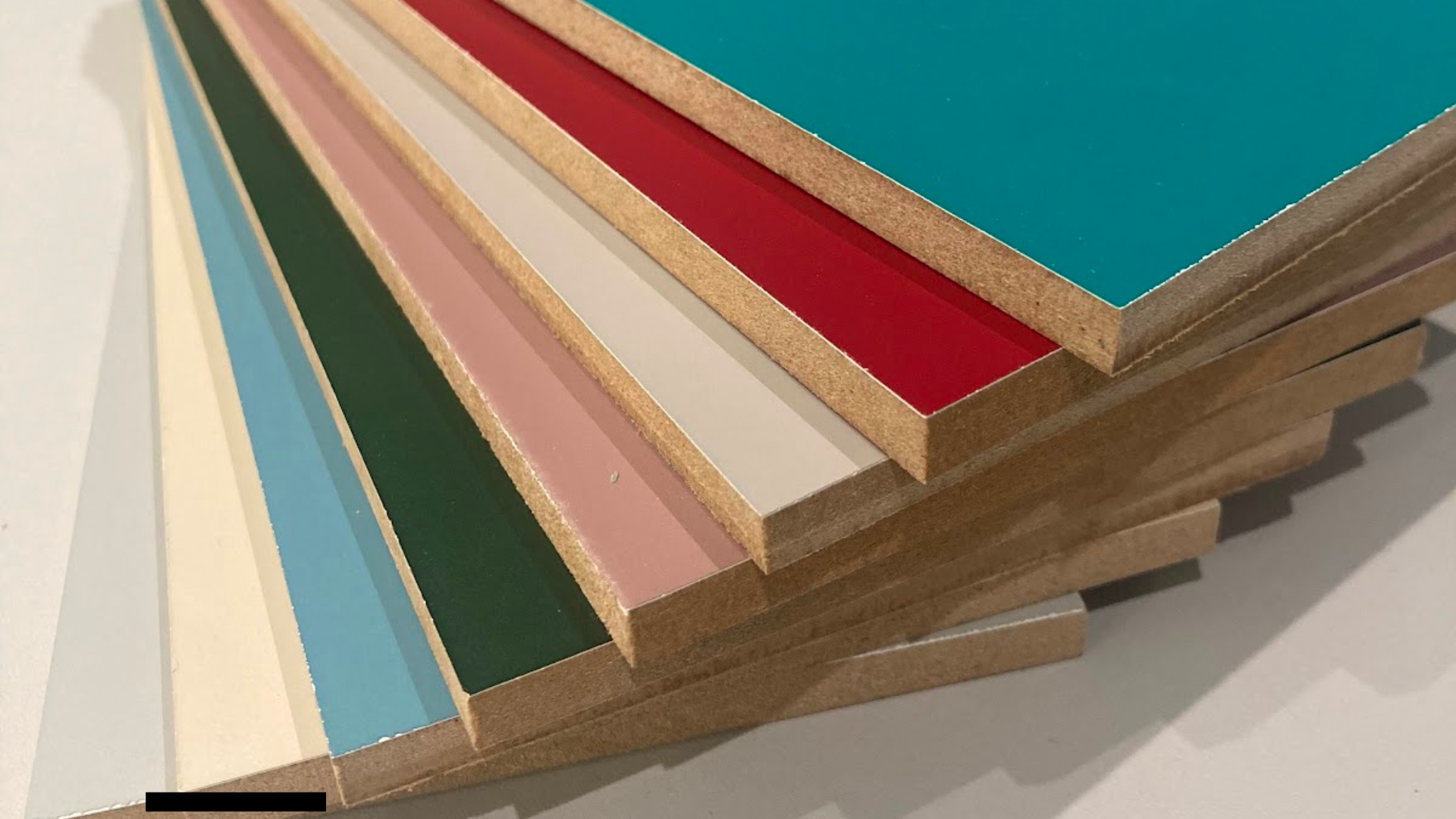

A clear and pigmented system with various sheen levels available, allowed for all job requirements to be covered.

Whether it be clear or pigmented, the specified system is 3 coats throughout, consisting of two base coats and one topcoat. This allows for the production manager to schedule specific time allocations for all jobs, regardless of what the client requirements are.

With both systems having the usual alkyd PU mixing ratio of 2:1, the product provides fast drying and durable properties, to add to the main benefit the FR certificate achieves.

Stay In The Loop

Receive Regular Newsletters Straight To Your Inbox

Be the first to receive all the latest articles, tips, tricks, quizzes, calculators, industry advice & news that will land straight into your email inbox!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book A FREE Discover Session

Take The Next Step Towards Improving Your Coating Processes

Discover the potential to optimise your finishing for maximum efficiency.

Increase Your Productivity

Improve Your Profitability

Enhance Your Performance

Increase Your

Productivity

Improve Your

Profitability

Enhance Your

Performance

When it comes to coating systems, you can’t afford to take chances.

Kortec’s approach is

tested and proven to work.